More than a decade later, the brainy nuances of the caliber 31-260 REG QA remain as scintillating and unusual as ever. No wonder this is popping up on collector wish lists everywhere.

As the title suggests, this is a closer look at the movement of the Patek Philippe Annual Calendar Regulator. It follows on the heels of the previous piece we published that served more as an overview. When I look at this watch, I think about the historical function of regulator clocks while simultaneously thinking about the Patek Philippe caliber 31-260 REG QA – built exclusively to power their first-ever Regulator wristwatch, the Ref 5235G. This caliber tells a beautiful story of efficient energy transmission, and I continue to study it on a deeper level. It’s not a timepiece overflowing with complications – it’s the base caliber watchmaking I’m most interested in here – and I will share why.

On the face of it, we see the distinct Regulator dial arrangement. This configuration of a center sweep minute hand combined with subsidiary hours at 12 o’clock and subsidiary seconds at 6 o’clock – pays tribute to a bygone era when free-standing pendulum clocks were relied upon in watchmaking workshops and observatories. An exceptional example of one quietly stands in the office of Mssr Philippe Stern from the early 1900s. These clocks kept precise time for over 200 years until quartz-powered instruments upended them.

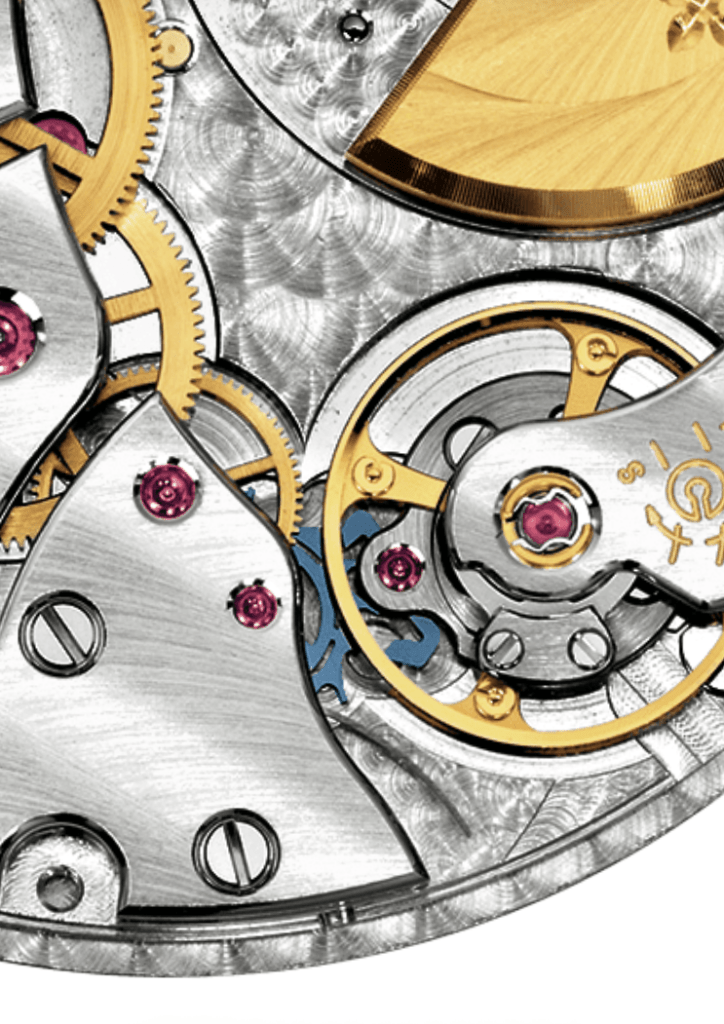

The genius of this non-coaxial layout is that it provides an unobstructed view of the minute hand – which was paramount for watchmakers. Moving the hour display off-center prevents it from sweeping over and partially covering the minute hand for several hours throughout the day. Reading this quirky dial requires some practice, but I enjoy its rich, historic nature. With every glance, it’s like looking at the past. Turn it over, and you see sparkly modern details among the gleaming traditional Swiss artistry.

New model. New movement.

When designing a new model, it is common for Patek Philippe to endow it with new technology, and inside the classic Calatrava case of the Regulator is just that, an all-new caliber. Inspired by the caliber 240, it is Patek Philippe’s first ultra-thin self-winding movement with a mini-rotor that displays the subsidiary seconds at 6 o’clock (rather than the customary 4 o’clock position). It is also the very first – entirely new – basic movement designed to accommodate components made of Silinvar®: The Spiromax® balance spring, invented in 2006, and the Pulsomax® escapement, invented in 2008, are both made of this innovative silicon-based material. These slick components represent the high-tech twist on this watch.

Silinvar® technology was an in-house material made by the Advanced Research department. For James Bond fans, this department is similar to MI6’s “Q Branch” – and even Lockheed Martin’s “Skunk Works” Division in how they operate. The Advanced Research team stealthily develops cutting-edge secret technology to advance Patek Philippe’s watchmaking arts – and their Silinvar® smart material does just that.

This unique material is anti-magnetic, remarkably shock-resistant, non-corroding, and capable of delivering higher performance without lubrication. These are critical advantages. The next step was creating harmony in motion between these new-age components and traditional ones. A challenging task. So, would it work? A more obvious question: Why not use the existing caliber 240?

Why not use the caliber 240?

Launched in 1977, the caliber 240 features a 22K gold mini-rotor recessed in the main plate; this allows for a low profile of just 2.53mm in height – a point of inspiration for the caliber 31-260. However, it places the second hand at the 4 o’clock position – not the 6 o’clock position needed for a regulator. Ultimately, the engineers went beyond simply reworking the existing ticker to accommodate a subsidiary-second hand at 6 o’clock. Where’s the fun in keeping things simple, right? Instead, they constructed the caliber 31-260, a brilliant manifestation of watchmaking that more efficiently meets Patek Philippe’s standard accuracy rate of -3/+2 seconds per day. Now, we’re going to unpack it.

Silinvar® technology and beyond

For this storied manufacturer, it was the very first time that a movement was designed entirely from the ground up for oscillator bits made of Silinvar® – these are the Spiromax® balance spring and the Pulsomax® escapement. The enhanced isochronism of the Spiromax® hairspring and the improved flow of energy provided by the Pulsomax® escapement generate a higher accuracy rate and long-term dependability.

Here’s a part that I love…

The gear train transmits the power from the mainspring barrel to the escape wheel – so it needs to keep the supply flowing. To fully maximize the full might of the Pulsomax®, the wheels in the gear train underwent a sharp enhancement to support the quicker pace of the escapement. A faster working escapement deserves an optimized gear train, right?

I’ll explain.

As gears mesh together, energy is handed off from wheel to wheel – this must happen without losing power. And when you have parts making contact – or gears meshing together – you generate friction. Reduce friction in this space and receive an upside in production. That’s precisely what the engineers did. They smartly decided to modify select gears to engage with smoother contact. Now, when they meshed together, they encountered less friction and gained a boost in energy flow through the movement. This heavenly blend of mechanical ingenuity meant that Patek Philippe now had a timekeeper producing abundant energy with far less degradation.

Unusual frequency of 3.2 hertz

While the caliber 240 beats at a rate of 21,600 vibrations per hour (3Hz), the frequency of the new 31-260 was increased by nearly 10% to 23,040 vibrations per hour (vph) – which is equivalent to 3.2 Hz while – get this – increasing its power supply. A watch running at a higher frequency tends to use more power – not less.

Thanks to the added effectiveness of the gear train and escapement, it was possible to reduce the tension of the mainspring and the overall forces to which the wheels are exposed. Why is this important? Because friction is the enemy. Relaxing the tension further diminishes friction between the delicate wheel pivots and the bearing jewels, enhancing longevity and reliability.

Compounding efficiency leads to greater power reserve

Despite its elevated frequency, the new caliber 31-260 REG QA has a power reserve of up to 60 hours as opposed to the 48-hour range of the caliber 240. When a movement draws power for this length of time from only one mainspring barrel, there tends to be a tapering in performance in the later stages. This is due to a loss of torque as the spring relaxes. This challenge is nothing new and remains a constant focus for manufacturers striving for longer intervals: how to maintain stable power – and steady rate accuracy – from a fully wound state to an unwound state.

A straightforward example I’ve used in training is comparing a mainspring barrel to a car’s fuel tank. The barrel is the fuel tank; the mainspring (coiled inside the barrel) is the fuel. A larger tank fits more fuel and can take you farther. However, it’s not practical to continue increasing the tank size for greater fuel range. It would be best to engineer an economical solution maximizing fuel.

Now, back to watchmaking…

Certain makers opt for an additional mainspring barrel (similar to adding an extra fuel tank) to increase power reserve. This is a fine solution if the most significant problem being addressed is extended power supply, and space is available inside the caliber to fit another barrel (that’s a whole different topic for another day). By incorporating Silinvar®, Patek Philippe now has an efficient lightweight transmission – rather than the heavier steel transmission traditionally used. This means the caliber 31-260 requires less energy and friction to turn those gears, keeping more power reserve in the bank without a loss of torque. The final end result: greater accuracy rate over a longer period of time.

Pretty remarkable, right?

Key figures and final thoughts

I geek out over the way this subtly refined gear train unites with the exotic Silinvar® machinery to make this caliber soar. The finished product represents a tapestry of masterful problem solving while harvesting various advantages. When considering the 10% higher frequency and the 25% higher power reserve, it adds up to an efficiency increase of about 30% (rounding down) when directly compared to the caliber 240. But nothing in watchmaking is ever perfect, and new technology often comes with growing pains.

Following the initial unveiling in 2011, additional tweaking was necessary, and deliveries were delayed. As I mentioned in the previous piece we published on this model, the 31-260 has the pedigree of a racing engine. It’s more sophisticated and features advancements beyond its Silinvar® internals – the star players in this movement – so additional analysis of its behavior was needed. This caliber is as unique as you’ll find among Patek Philippe’s “regular” production portfolio, and a rarity that collectors are now keen to snatch up.

Despite its early setback, the Regulator is another chapter in this manufacturer’s innovation story. New technology can deliver results; sometimes, it just needs assistance to reach another level. This is why I share the nuance of the gear train; it represents a fine watchmaking detail that can easily be overshadowed. Patek Philippe could create an entire movement in Silinvar®, but they would sacrifice that warm fingerprint of tradition still present here and throw away all the hand-finished elegance. This ticker beautifully eradicates the sting of friction while reaping tremendous performance benefits – all in a traditional Swiss package with the right volume of forward-thinking spirit.

Again, nothing ever rises to the level of total perfection – Mssr Thierry Stern is the first to admit that – but that doesn’t make the ultra-fine, purposeful detailing any less alluring. In the end, we must find the flaws we can live with. In the meantime, I’ll continue seeking more compelling works created by brilliant engineers and gifted artisans embodying luxurious details. The ones we can’t live without.